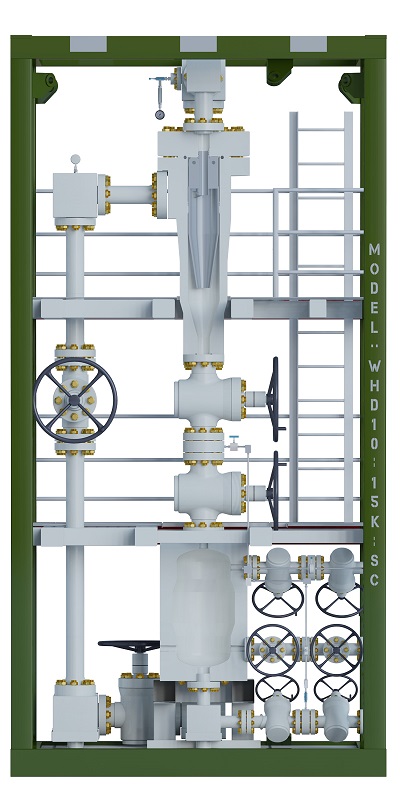

Wellhead Desander

Send us an enquiry by downloading the Input Data Sheet, and return to us at sales@eprocess-tech.com

The Wellhead Desander by eProcess is a fit-for-purpose multiphase solid-fluid cyclone designed to treat full wellstream flow. This technology can be installed upstream of the wellhead choke (wellhead desanding) or between the choke and production separator (wellstream desanding). Designed specifically for mixed gas, oil, water flow streams the Wellhead Desander can operate from 0-100% gas void fraction and is equally applicable on gas or oil wells. The Wellhead Desander is used for ongoing sand production in process facilities or for temporrary solids productions during well testing and clean-up. Supplied in either component or skid-based format the Wellhead Desander is available in ASME (150#-1500#) and API-6A (5K-15K) design ratings.

eProcess Wellhead Desander cyclones are pressure drop dependent, where multiphase fluids are directed into the cyclone causing the fluids to spin under a centrifugal force. These strong forces cause the solids and fluids to separate.

Gas in particular, disengages and separates quickly. The heavier solids are forced outward toward the cyclone wall, and the lighter fluids and gas phases migrate in the opposite direction toward a centre core.

Solids spiral down the cyclone to the underflow outlet, while the remaining fluids are forced in the opposite direction to the overflow. The process is a simple and effective separator, with a 2-3 second retention time, and no moving parts. Solids are removed from the accumulator in batch operation while the Wellhead Desander unit remains on-line.

Applications:

- Produced Sand Removal

- Well Testing Operations

- Coiled Tubing Cleanup

- Underbalanced Drilling Operations

Benefits:

- No moving parts combined with low maintenance and downtime result in significant capital and operating cost savings

- Compact – 10% of the size and weight of conventional filter systems provide easier mobilization

- Activates oil and gas wells previously shut-in due to excessive sand production

- Eliminates solids erosion on downstream pipework, valves, chokes, and process vessels

- Provides solids removal prior to oil contamination which eliminates sludge formation and other difficult solids accumulation problems

Operations:

- Wellhead Desanders are available in a range of sizes and are designed to separate 98% of particles from 5 to 50 microns and larger, and up to 99% by weight

- Operating pressure drop requirements vary from 5 to 75 psi, with the larger units handling solids volumes of up to 20% and the smaller units handling up to 1-2% by volume

Storage & Transportation:

- Solids are typically collected into a dedicated secondary accumulator vessel. At high operating pressure the accumulator prevents high quantities of gas flashing to atmosphere during the purge cycle

- To ensure liquids content in the final batch is minimized, water is reduced by the use of a filter-bin. The solids remain and the water is collected and pumped to a slops tank. The final sand slurry is typically >90% solids by volume.

- The collected solids are removed either by tank replacement or by vacuum truck operation