FSM eBlog

Facilities Sand Management farewell…prepare for Produced Water Debottlenecking and Partial Processing in 2023. (B-FSM-200)

Facilities Sand Management farewell…prepare for Produced Water Debottlenecking and Partial Processing in 2023. (post B-FSM-200) This series on Facilities Sand Management…

Facilities Sand Management Training Course Videos – CC in English and Spanish (B-FSM-199)

Facilities Sand Management Training Course Videos – CC in English and Spanish (B-FSM-199) eProcess put our Facilities Sand Management course on-line…

Facilities Sand Management Case Studies (B-FSM-198)

Facilities Sand Management Case Studies (B-FSM-198) A helpful tool in designing a Facilities Sand Management system is to see what other…

Facilities Sand Management: Key Technical Papers (B-FSM-197)

Facilities Sand Management: Key Technical Papers (B-FSM-197) At the end of each of the eleven training modules on Facilities Sand Management,…

FSM eBlog – The Five Most Important Posts (B-FSM-196)

FSM eBlog – The Five Most Important Posts (B-FSM-196) As we near the end of eBlog posting series on Facilities Sand…

FSM Demo Videos – CC in English and Spanish (B-FSM-195)

FSM Demo Videos – CC in English and Spanish (B-FSM-195) eProcess has put together a series of FSM equipment demonstration videos…

Facilities Sand Management Calculation Exercises (B-FSM-194)

Facilities Sand Management Calculation Exercises (B-FSM-194) This post provides calculation exercises based on material previously posted. You will need to first…

Heavy Oil & Viscous Fluid Sand Management – Key Items and Technical Paper References (B-FSM-193)

Heavy Oil & Viscous Fluid Sand Management – Key Items and Technical Paper References (B-FSM-193) This post concludes the discussion on…

Recommendations for Sand Removal in Heavy Oil Production (B-FSM-192)

Recommendations for Sand Removal in Heavy Oil Production (B-FSM-192) Bringing together the last several posts we now can make recommendations for…

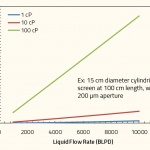

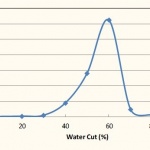

Effects of Viscosity on FSM Unit Process Components (B-FSM-191)

Effects of Viscosity on FSM Unit Process Components (B-FSM-191) In this posting we look at the effect of increased viscosity on…

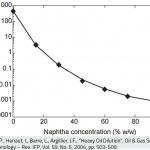

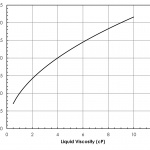

Reducing Oil Viscosity – Options for FSM (B-FSM-190)

Reducing Oil Viscosity – Options for FSM (B-FSM-190) A multitude of options are available for reducing the continuous phase viscosity –…

Effects of Fluid Properties on FSM – Minor to Major Effects (B-FSM-189)

Effects of Fluid Properties on FSM – Minor to Major Effects (B-FSM-189) In ranking fluid property effects on Facilities Sand Management…

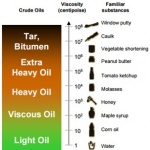

Other Viscous Fluids in Oil Production & Processing (B-FSM-188)

Other Viscous Fluids in Oil Production & Processing (B-FSM-188) Aside from heavy oil, there are many viscous fluids encountered in oil…

Heavy Oil and Important Aspects for FSM (B-FSM-187)

Heavy Oil and Important Aspects for FSM (B-FSM-187) What is Heavy Oil?From SPE PetroWiki heavy oil is defined as that with…

Heavy Oil & Viscous Fluid Sand Management – Goals and Objectives of FSM Module 11 (B-FSM-186)

Heavy Oil & Viscous Fluid Sand Management – Goals and Objectives of FSM Module 11 (B-FSM-186) We now move on to…

Demonstration Video 4 – Offshore FSM System (B-FSM-185)

Demonstration Video 4 – Offshore FSM System (B-FSM-185) A series of equipment demonstration videos have been produced to show the process…

Demonstration Video 3 – eJECT Operation (B-FSM-184)

Demonstration Video 3 – eJECT Operation (B-FSM-184) A series of equipment demonstration videos have been produced to show the process operations…

Demonstration Video 2 – Accumulator Operation and Purge (B-FSM-183)

Demonstration Video 2 – Accumulator Operation and Purge (B-FSM-183) A series of equipment demonstration videos have been produced to show the…

Demonstration Video 1 – Liquid Desander Operation (B-FSM-182)

Demonstration Video 1 – Liquid Desander Operation (B-FSM-182) A series of equipment demonstration videos have been produced to show the process…

The Subsea Wellhead Desander (B-FSM-181)

The Subsea Wellhead Desander (B-FSM-181) The subsea wellhead desander is surface technology applied subsea. It uses well-proven multiphase desander technology packaged…

Subsea Sand Management – Recommendations and Conclusions (B-FSM-180)

Subsea Sand Management – Recommendations and Conclusions (B-FSM-180) If sand produced to subsea facilities…Not excluded by completion equipment or production limitsSeparate…

Subsea Sand Management – Path C: Removal With Disposal (B-FSM-179)

Subsea Sand Management – Path C: Removal With Disposal (B-FSM-179) After separation reintroduce to production line (bypass method)New flow streamPut sand…

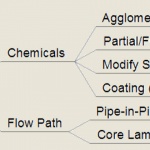

Subsea Sand Management – Path B: Treatment (Particles or Flow Path) (B-FSM-178)

Subsea Sand Management – Path B: Treatment (Particles or Flow Path) (B-FSM-178) The Treatment Approach seeks to modify either the sand…

Subsea Sand Management – Path A: Conventional Approach (B-FSM-177)

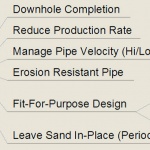

Subsea Sand Management – Path A: Conventional Approach (B-FSM-177) The Conventional Approach uses known or standard methods or technology.Exclusionary ProductionInstall downhole…

The Subsea Sand Management Challenge (B-FSM-176)

The Subsea Sand Management Challenge (B-FSM-176) What to do with the sand? That is the subsea sand management challenge. It is…