Produced Water Treatment with Deoiling Hydrocyclones - Misconceptions & Corrections (B-PWT012)

Misconception 4 : Deoilers Do Not Work in High Pressure Gas Condensate Systems

Correction 4 : Deoilers work every bit as well, if not better, in high pressure gas condensate systems. The main issue to address here is the pressure profile limits required to ensure the Deoiler is running within its operating envelope.

The misconception here has come about due to the assumption that gas condensate systems contain very small drop sizes and that these prevent the Deoiler from operating efficiently.

Although it’s true that condensate has a higher propensity to shear into small drop sizes given a sizable pressure drop source, this isn’t the problem here.

Produced water in gas condensate systems almost always exists at the higher end of design and operating pressure in the production facility. Operating pressures in excess of 600-800 psig are common. This high pressure source produced water always contains a substantial amount of dissolved gas, and any slight reduction in pressure results in the breakout of this gas.

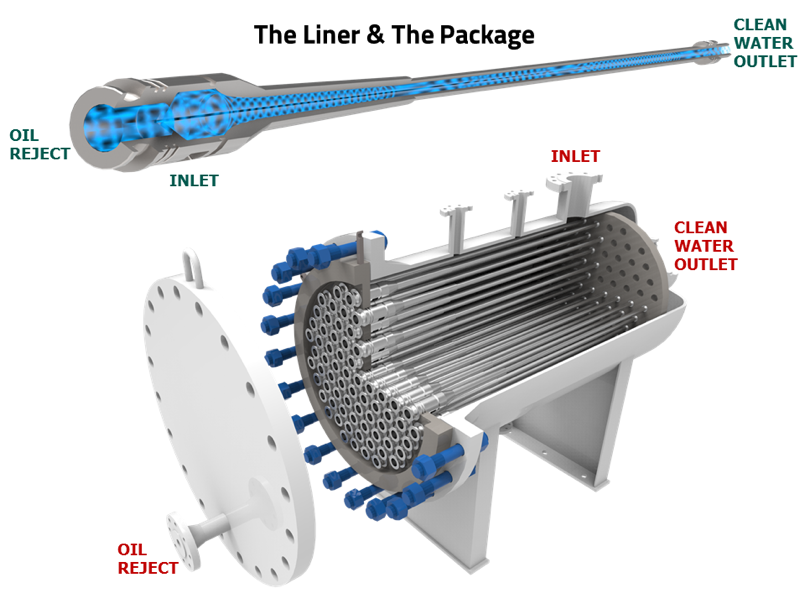

The Deoiler liner is an oil water separator, and is not designed to deal with gas as well. Any free gas has a detrimental effect on performance, although some gas can be handled in the vessel ‘package’. Now we saw that the Deoiler is a simple, but effective, separator with a 2-3 second residence time and no moving parts.

However the pressure drop required through the Deoiler always results in some gas breakout. The amount depends on the operating pressure, the volume of dissolved gas, and other process conditions. Due to the short residence time in the Deoiler, this gas breakout occurs after it exits the Deoiler, without effecting the Deoiler performance – up to a point.

At increasing flowrates, experienced in gas condensate systems due to the high operating pressure available, this gas breakout can occur within the Deoiler liner. The free gas displaces the oil core to exit through the overflow reject stream. The oil is then choked away from the reject port and exits with the water, resulting in poor performance.

The answer here is to restrict the pressure drop through the Deoiler to a nominal maximum, to ensure the gas breakout does not occur within the Deoiler liner. This nominal maximum pressure drop is around 400 psi, from inlet to reject outlet. The actual figure should be evaluated from field testing beforehand or during commissioning.