Separator Jetting – Design Procedure Parts 3-4 for Spray Jetting (B-FSM-119)

This post continues the design procedure for a traditional spray jetting system that should be followed by anyone using this technology in their separators. This design procedure is taken from Priestman et al. (reference at end of article) and is the best I have found. Get a copy of his paper and read thoroughly – then follow the design procedure. Their methodology was developed from lab tests using horizontal tanks at atmospheric pressure.

Design Procedure – Part 3

Design analysis will consider various options available

- Jetting fluid to be pumped higher than vessel operating pressure

- Vessel operating pressure will change over time

- Required jetting flow (may be low quantity of clean fluid)

- High differential pressure reduces water usage

- However, vessel wear increases with differential pressure

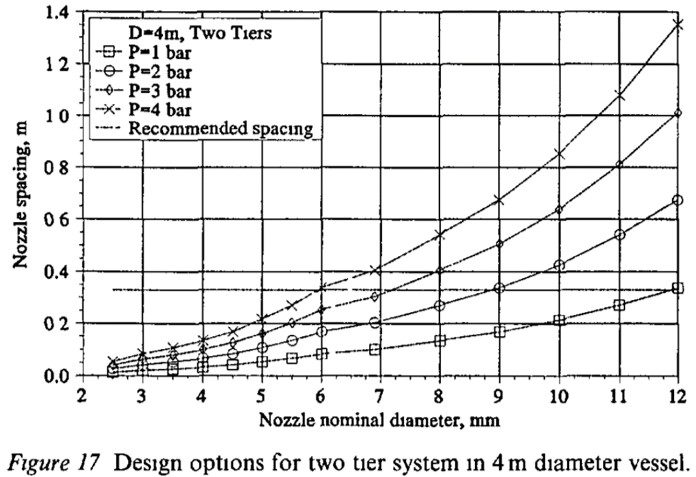

The information above is shown graphically in the header figure.

Design Procedure – Part 4

Vessel drain located at 3D spacing

- Each zone operated sequentially

- Have own discrete wash loop

- Drain loop separated by low baffle

Discharge from vessel until outlet solids drops below 5 vol. %

- Measure with gamma ray densitometer

- Longer washing causes interference with oil-water interface

Total jet flow (in) and discharge flow (out) should be equalized

Drain points covered with sand cap

- Sand pans not proven useful

- Sand cap flat circular disc twice the drain diameter and placed at height 0.375 times drain diameter (must allow passage of largest solid particle)

Heavy oil with stick sand requires higher F-factor and closer drain spacing

Next week I will discuss the controls for traditional spray jetting systems.

References:

- Priestman, G.H., Tippetts, J.R., Dick, D.R., “The Design and Operation of Oil-Gas Production Separator Desanding Systems”, Trans IChemE, Vol. 74, Part A, March 1996, pp. 166-176.

- Rawlins, C.H., “Design of a Cyclonic Solids Jetting Device and Slurry Transport System for Production Systems”, paper 166118, presented at the SPE Annual Technical Conference and Exhibition, New Orleans, LA, 30 September – 2 October, 2013. https://doi.org/10.2118/166118-MS