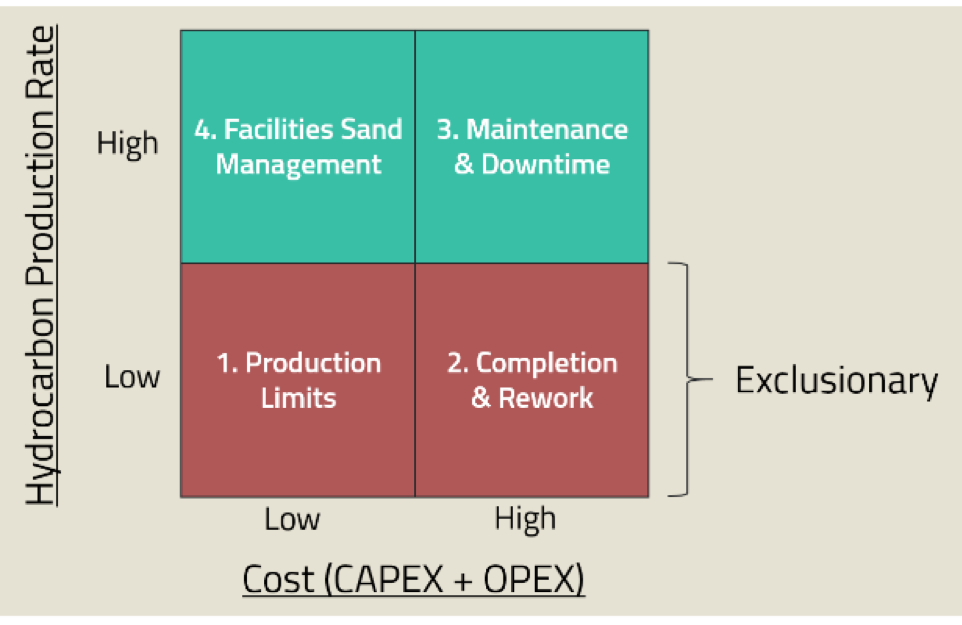

Should Sand be Excluded from Well Production? (B-FSM002)

Exclusion Methodology focuses on preventing

sand from flowing into the wellbore – then to the surface. However, these

controls come with a cost.

Quadrant 1: Production Limits

Goal: To reduce oil and gas production to

sand free production rate

- Easy to implement – however

results in immediate reduction of hydrocarbon flow - Sand production map is moving

target (requires frequent monitoring/adjustment) - Use sand monitoring/measurement

probes and sampling - If choke too much then lost

production, If choke to little then sand in separator - CAPEX: Low | OPEX: Low |

Production: Large Decrease

Quadrant 2: Downhole Equipment

(Completions)

Goal: Prevent sand ingress from reservoir

to wellbore tubulars

- Use Completion design and technology

- Widely studied, accepted, and

available technology - May introduce formation/skin

damage and reduce inflow - Does protect mechanical

stability of well area - Eventual mechanical failure

- Can be very expensive to replace,

especially in deepwater - CAPEX: Medium-High | OPEX: Low

| Production: Small Decrease

What if sand were allowed to flow instead

of being choked back? It is possible that more oil can be produced with a lower

total well cost.

Bibliography:

- Andrews, J., Kjørholt, H., and

Jøranson, H. 2005. Production Enhancement from Sand Management Philosophy. A

Case Study from Statfjord and Gulfaks. Paper 94511 presented at the SPE

6th European Formation Damage Conference, Scheveningen, The Netherlands, 25-27

May. - Fadillah, P.M., Ahmad, P.H.,

Ward, M. et al. 2004. Gecko Wells: Bringing Sand to Surface, a Change in Well

Design Philosophy. Paper 87956 presented at the IADC/SPE Asia Pacific Drilling

Technology Conference and Exhibition. Kuala Lumpur, Malaysia, 13-15 September. - Geilikman, M.B., Dusseault,

M.B., and Dullien, F.A. 1994. Fluid Production Enhancement by Exploiting Sand

Production. Paper 27797 presented at the SPE/DOE Improved Oil Recovery

Symposium. Tulsa, Oklahoma, 17-20 April. - Guinot, F., Douglass, S.,

Duncan, J. et al. 2009. Sand Exclusion and Management in the Okwori Subsea Oil

Field, Nigeria. Paper 106294 in SPE Drilling & Completion 24 (1):

157-168. - Kaura, J.D., Macrae, A., and

Mennie, D. 2001. Clean up and Well Testing Operations in High-Rate Gas-Condensate

Field Result in Improved Sand Management System. Paper 68747 presented at the

SPE Asia Pacific Oil and Gas Conference and Exhibition. Jakarta, Indonesia,

17-19 April. - Sanfilippo, F., Brignoli, M.,

Giacca, D. et al. 1997. Sand Production: From Prediction to Management. Paper

38185 presented at the SPE European Formation Damage Conference. The Hague,

Netherlands, 2-3 June. - Selfridge, F., Munday, M.,

Kvernvold, O. et al. 2003. Safely Improving Production Performance through

Improved Sand Management. Paper 83979 presented at the Offshore Europe.

Aberdeen, UK, 2-5 September. - Vaziri, H.H., Lemoine, E.,

Palmer, I.D. et al. 2000. How Can Sand Production Yield a Several-Fold Increase

in Productivity: Experimental and Field Data. Paper 63235 presented at the SPE

Annual Technical Conference and Exhibition. Dallas, TX, 1-4 October.