Liquid Desander - Particle Travel in a Flooded-Core Hydrocyclone (B-FSM066)

Note: The material presented in this article is taken from the Facilities Sand Management training course – Module FSM-M4: Liquid Desander. For more information click here.

We now begin discussion of an advanced concept in working with desander technology. As mentioned in post B-FSM-045 (19-Jun-18) the desander was originally developed for removing very dilute amount of sand particles from agricultural spray water. The sand concentration in this well flow was ~10 ppm. With desander deployment for produced water treatment the solids concentration began to creep up to 100-500 ppm solids – and the desanders continued to work well.

However, much like the Peter principle in management, the desander finally rose to its level of incompetence. The boundaries of operation – in terms of solids concentration – were continued to be pushed until the desander no longer worked well. This came about when trying to use small diameter desanders (with small separation size) in applications very high concentration of solids (>10,000 ppm).

For example, a desander using (38 mm) diameter liners works well to remove sand from produced water with 100 ppm of sand. However, that same desander should NEVER be used to treat separator jetting slurry with 25 wt.% solids. The high concentration of solids will overload the liners – leading to loss of separation and eventual erosion failure of the liners.

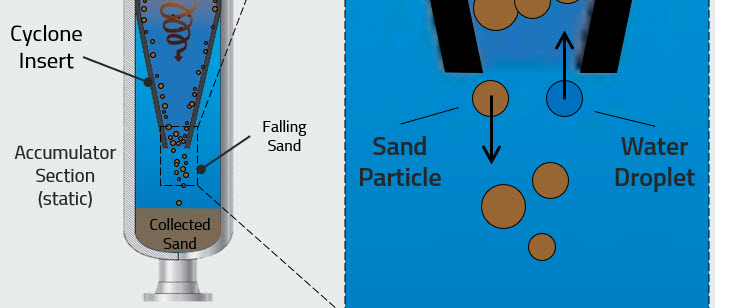

To explain this phenomenon, and offer a potential solution, we start with the concept of a flooded-core hydrocyclone. This term was introduced in post B-FSM-049 (17-Jul-18). It means that, unlike a mining cyclone, the desander cyclone operates without an air-core in the central vortex. The desander is fully “flooded”, because the accumulator is fully enclosed. The figure below illustrates the details.

The entire body (length) of the cyclone cylinder and cone, as well as the accumulator, are fully flooded (i.e. no air-core in the vortex). Also, the entire cylinder, cone, and accumulator section are fully enclosed. There is only one inlet and one outlet – through the desander inlet and overflow nozzles, respectively. All fluids entering the desander exit through the top. The solids however are separated to slowly collect into the accumulator.

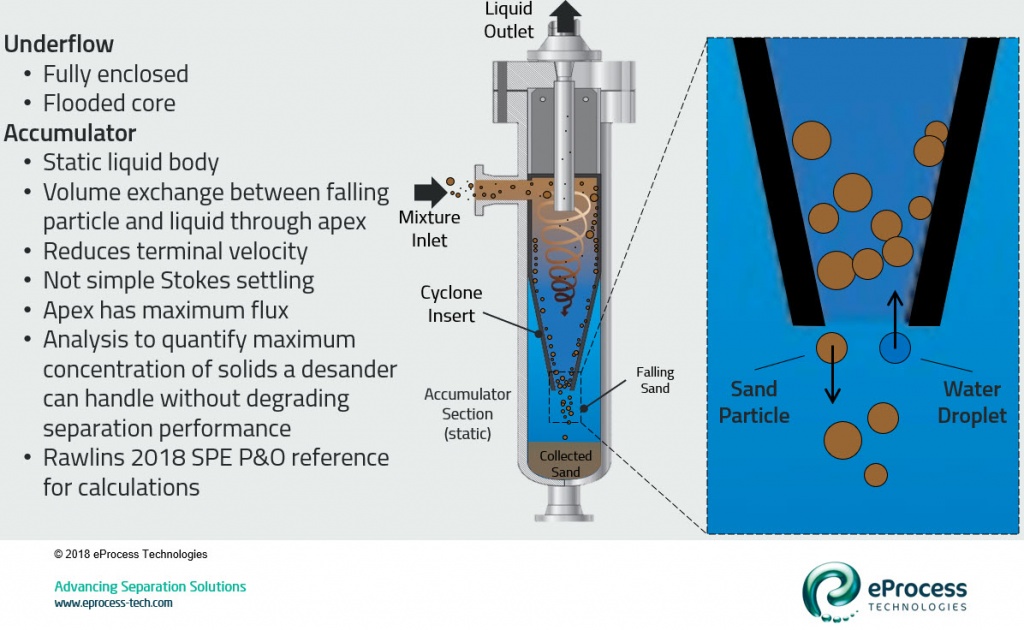

Each sand particle that is separated (i.e. greater than the D98) reports to the apex of the cone to fall into the accumulator. The particle is exhibiting very high rotational forces as is migrates to the bottom of the cone – but the vortex forces are fully arrested as soon as the particle reaches the apex. The particle effectively stops – then falls due to gravity into the accumulator.

Since the accumulator is enclosed, the only entrance and exit is through the cyclone apex. As a particle falls from the cone through the apex and into the accumulator is displaces an equivalent volume of liquid. This displaced liquid can only go back up through the apex and eventually report to the desander overflow. This is particle-fluid volume swapping.

The velocity of the falling particle does not follow a simple Stokes settling relationship. The upward fluid velocity hinders the downward motion of the particle. There will be a maximum point where the volume of particles trying to settle is balanced by the upward fluid velocity and the apex will “choke” – preventing any more solids from reaching the accumulator.

This choke point, or apex flux, determines the maximum concentration of solids a specific desander in a specific process before failure due to overload.

A laboratory investigation, as detailed in the reference – and detailed in the next three posts, performed analysis to quantify the maximum concentration of solids a desander could handle without degrading separation performance.

The next article will provide further details, and photos, on apex choking by particle overload.

References:

- Rawlins, C.H., “Particle Transfer Between the Cyclone and Accumulator Sections of a Desander”, SPE Production & Operations, paper SPE-191147-PA, 2018.