Deoiling Hydrocyclones

Send us an enquiry by downloading the Input Data Sheet, and return to us at sales@eprocess-tech.com

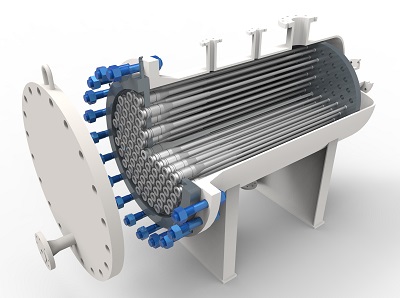

Hydrocyclone based process systems are the most cost-effective solution for produced water treatment clean up. Located directly downstream on the water outlet of the production separator and upstream of the water level control valve, these systems operate in a proportional “pressure ratio” control manner.

eProcess Deoiler hydrocyclones are pressure drop dependent, where fluids are directed into the deoiler tube causing the fluids to spin under a centrifugal force. These strong forces cause the two immiscible liquids (oil and water) to separate. The heavier water phase is forced outward toward the cyclone wall and the lighter oil phase migrates toward the center core.

By accurately controlling the pressure differential across the hydrocyclone the water phase is sent in one direction to the underflow, and the oil phase is sent in the opposite direction to the overflow. The process results in a simple and effective separator with a 2-3 second retention time and no moving parts.

Applications:

- Pre-separator and Dehydrator capabilities

- Produced Water Cleanup

- Free Water Knockout

- Downhole Water Reinjection

Benefits:

- No moving parts

- Compact – 10% the size and weight of conventional systems

- Performance unaffected to external motion

- Most efficient and cost effective solution to water treatment problems

Operations:

- Deoilers typically separate more than 99% by volume of the lighter oil phase with particle >10 microns

- Produced water streams typically contain 1000-5000 ppm oil. At these concentrations a hydrocyclone based system will clean water to the range of 10-40 ppm.

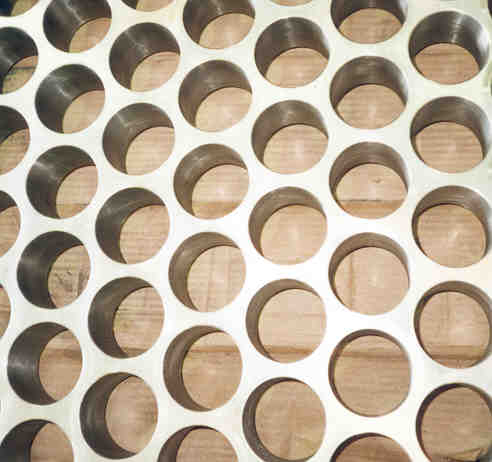

- Individual hydrocyclone capacities are dependent on the available pressure and the type of cyclone used. Smaller high efficiency cyclones range from 80-500 BWPD per tube, while larger capacity cyclones range from 450-3000 BWPD per tube.

- Innovative pressure vessel packaging ensures any customer turndown requirement can be met, on-line, without downtime

Degasser/IGF Systems:

- The most effective performance solution to tough water treatment problems is a Deoiler/Degasser-IGF process system

- A Degasser-IGF will remove flashed gas, especially in high pressure systems, and utilize this gas to provide additional water polishing leading to a further 60 – 80% reduction in oil in water content

- The footprint of the Deoiler and Degasser-IGF system is typically 15% of the size and weight of conventional Free Water Knock-Out Drums, CPI’s, or Flotation units