Produced Water Treatment with Deoiling Hydrocyclones - Misconceptions & Corrections (B-PWT005)

Deoiling Hydrocyclones; A (brief) History : Part 1

Since its introduction to the upstream oil & gas industry in the mid 1980’s, the Deoiler hydrocyclone has been an efficient and economical solution for a large variety of produced water treatment applications. The separation task applicable with the Deoiler includes primary and secondary separation stages, depending on the problem at hand.

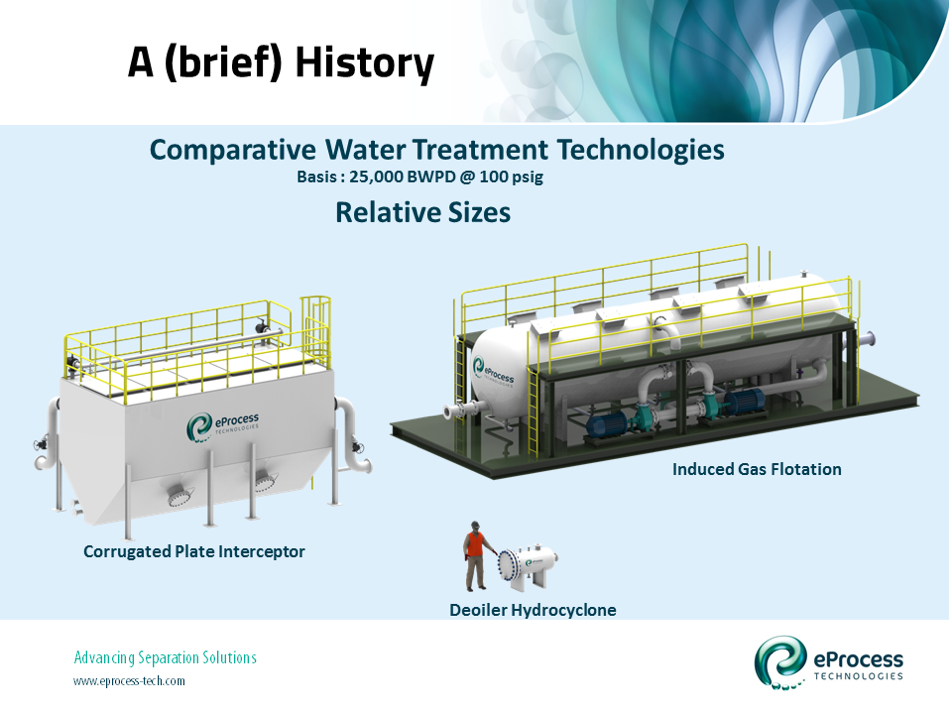

Initially Deoilers revolutionised the treatment of produced water streams, due to the fact that they were robust, efficient, simple to operate, and were a fraction (typically 10%) of the size and weight of their predecessors.

This meant that for ‘real estate challenged’ offshore facilities, there was a new solution capable of handling very large produced water volumes, in a small space, where previously there was none with the larger, heavier, older technology.

The early success of the Deoiler hydrocyclone stemmed from the significant amount of field test work performed offshore Australia and the North Sea. These initial test bed environments provided the (fortunately) ideal, high pressure – high temperature applications, which afforded successful outcomes, and allowed the technology to achieve a critical commercial foothold.

Subsequent regions and environments, notably North America, had less ideal process conditions (lower pressures and temperatures), and proved more of a challenge for the Deoiler, but subsequent technical progress and development over the years, went a long way to solve these more difficult applications.

Although a significant amount of field work was undertaken to the greater longer term benefit of the technology, the downside was that many end user operators had different experiences with the Deoiler, which was interpreted, incorrectly, as the capability of the technology, rather than the variation; the ease, or difficulty, of the separation task. As far as they were concerned all produced water was the same – right? This is an assumption which leads to frustration for any equipment vendor to this day.

Anyhow in the 1980’s the world appetite for crude was significant and growing, and increasing even faster was the relative amount of produced water co-produced with the crude. On average 3-4 barrels of produced water accompanies every barrel of crude, and in some locations this figure is a lot higher.

In 1993 A Norwegian Oil Industry Association Report commented;

From 1986 to 1993:

- Water production increased from 50,000 to 380,000 BWPD

- Oil in water concentration decreased from 40 to 20ppm

“In spite of a substantial water increase during the last years, the average oil concentration has declined and stabilized. This reduction is a direct consequence of retrofitting hydrocyclones on some of the major water producers.”

The Deoiler hydrocyclone’s time had come.

Following the success of the Deoiler technology, the removal of solids from produced water and multi-phase streams was undertaken with the ‘Desander’ and ‘Wellhead Desander’ technologies. See Dr. Hank Rawlins presentations in a separate series.

Bibliography:

- Rosie K., Conoco Inc., “Conoco’s Water Treatment Upgrade with Hydrocyclones”, Ocean Industry, Dec 1991 / Jan 1992.

- Choi M.S., Conoco Inc., “Hydrocyclone Produced Water Treatment for Offshore Developments”, SPE 20662, ATCE New Orleans, September 23-25, 1990.

- Meldrum N., Conoco UK Ltd., “Hydrocyclones: A Solution to Produced Water Treatment”, OTC 5594, OTC Houston, April 27-30, 1987.

- Hayes J.J., et al., Esso Australia Ltd., “Hydrocyclones for Treating Oily Water: Development and field Testing in Bass Strait”, OTC 5079, OTC Houston, May 6-9, 1985.