Wellhead Screen-Filter – Sand Management Options (B-FSM-100)

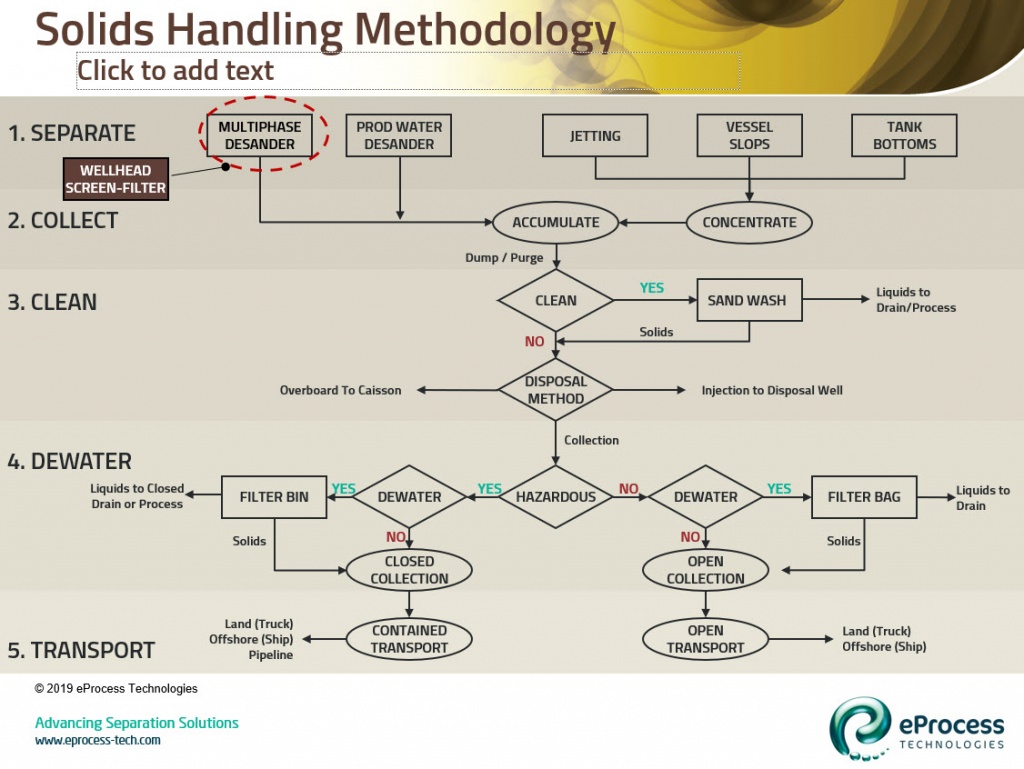

The wellhead screen-filter (WSF) is a piece of equipment used for separation. This it occurs in Step 1 of the Solids Handling Methodology flowchart. It sets in the same location as a multiphase desander – but does serve a slightly different purpose.

The Five-Steps of Sand Management

The core of solids handling for the upstream oil & gas industry – whether onshore or offshore – is to follow the Five-Steps of Sand Management. Most approaches for sand management focus on finding a piece of equipment to separate the sand – and assume the work is done. That is only Step 1. It is critical to follow all the steps.

The Wellhead Screen-Filter is used in Step 1 – separation of solids from the flow stream.

- Separate: Partition the solid particles from the liquid, gas, or multiphase stream

- Multiphase desander, filters, or existing three-phase separator

- Collect: Gather partitioned solids into one central location and remove from process pressure

- Desander accumulator vessel or vessel drains

- Clean: Removal of adsorbed hydrocarbon contaminants

- Recycle sand-wash systems

- Dewater: Removal of free water to minimize disposal volume

- Hanging mesh bags or screen lined bins

- Reduce the disposal volume by 90% and produce sand “cake” of <10 wt.% water

- Transport: Bring solids to disposal location

- Dependent upon the facilities location (onshore/offshore) and disposal requirements

- Options: Overboard discharge, landfill, ship-to-shore, slurry injection, etc.

Where to Remove Sand from Oil & Gas Facilities

Commensurate with knowing what problems sand causes – erosion, filling, interference, or increased OIW content – is then knowing where to remove the sand. A primary directive is to solve the right problem. If replacement of choke beans is a hindrance to sustained production, then remove the sand at the wellhead. However, if protecting the disposal reservoir from increasing injection pressure, then sand should be removed from the produced water stream.

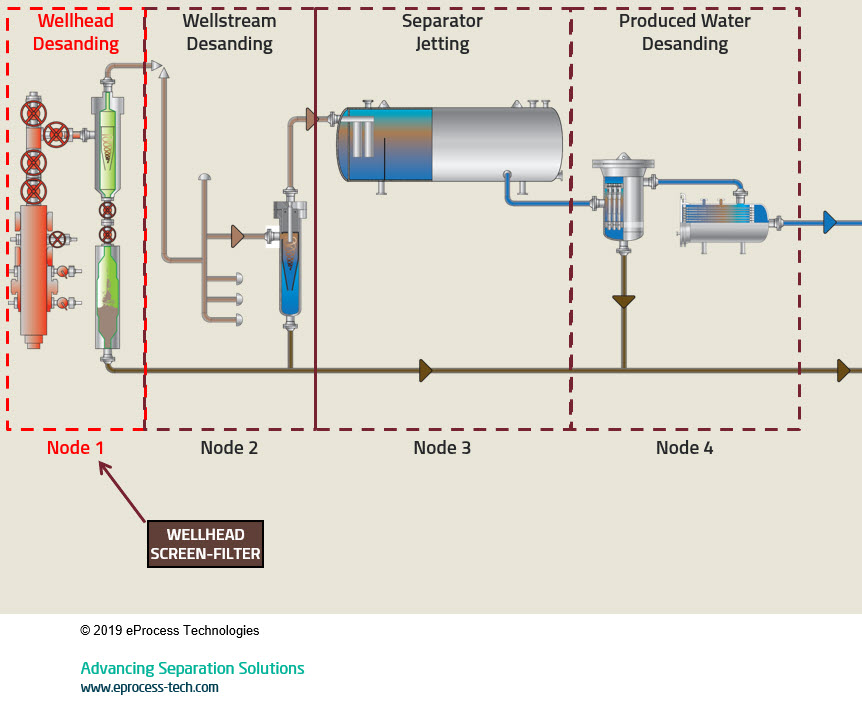

Sand is removed from facility flow in one of four nodes as shown in the header graphic. The WSF is used in Node 1- at the wellhead.

Node 1: Wellhead

- Multiphase flow at high pressure

- Sand removed prior to choke using multiphase desander or dual-pot sand filter

- Separation is easy due to low multiphase viscosity and sand easy to handle because of less complication from process chemicals

- Removal of sand here protects choke, manifold piping, production separator, and produced water equipment and disposal

References:

- Rawlins, C.H., “Sand Management Methodologies for Sustained Facilities Operations”, Oil & Gas Facilities, Vol. 2, No. 5, October 2013, pp. 27-34. https://doi.org/10.2118/1013-0027-OGF

Next week I will cover purpose and definition of the WSF and comparison to multiphase desander technology.