Multiphase Desander – Cyclonic Vs. Desanding Technology (B-FSM079)

(Note: Much of this information is a retelling of that presented in previous posts B-FSM-043 through -045.)

The Multiphase Desander is a derivative of the Liquid Desander which in turn is a derivative of Hydrocyclone Technology which is a subset of Cyclonic Technology. To fully understand the multiphase desander we must first start with fundamentals of Cyclonic Technology.

Definition of Cyclonic Unit Process:

Unit process converting potential energy of a fluid (pressure) at the inlet into rotating kinetic energy using only the shape of the device in order to partition two or more phases in that fluid into the respective number of concentrated outlet streams

What makes cyclonic technology so valuable for the offshore oil & gas industry is that it has the highest throughput-to-size ratio of any partitioning device. For a given flow rate a cyclone will have the smallest size and weight of any separation piece of equipment.

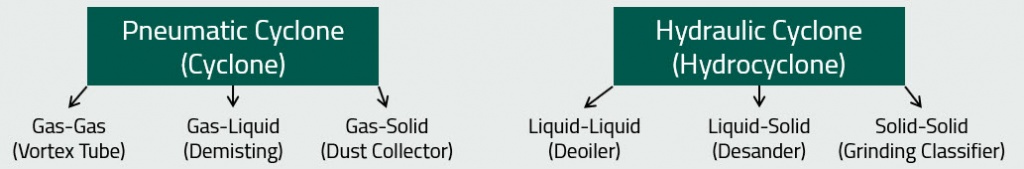

Cyclone Family

The nature of the fluid continuous phase is the first delineation in naming cyclonic unit equipment. If the fluid is a gas, then the unit is termed a Pneumatic Cyclone – if the fluid is a liquid then the unit is a Hydrocyclone. And correspondingly a Multiphase Cyclone treats gas-liquid mixed flow.

There are several key design and operating factors that define a piece of equipment as a cyclone unit process;

- No moving parts – no motors, no seals, no bearings, etc. – very simple machine

- Tangential or involute inlet – starts the swirling flow pattern

- Cylinder-cone geometry – increases swirl down the length of the unit

- Free-forced vortex split flow pattern – defines how the two exit-streams form and where the separated phase goes

- Classifying device – separates based on weight, not size

Hydrocyclones

The hydrocyclone is a contraction of the term “hydraulic cyclone” and signifies that the carrying fluid phase is a liquid. While the use is predominantly in aqueous systems with water as the carrying fluid, hydrocyclones can be used on any liquid. I’ve ran them on glycol, diesel, fruit juice, and picante sauce to name a few. The hydrocyclone is a subset of the cyclone unit process – it has the same features and benefits as previously discussed.

Desanders

The term “Desander” is short for the full name of Desanding Hydrocyclone. The desander is derived from the mineral processing hydrocyclone, thus is a subset of that technology. A technical term for the desander is a “flooded-core hydrocyclone”, since the encapsulation of the underflow prevents formation of the air-core – thus the body section is fully flooded.

The Multiphase Desander – first developed in 1994-1995 – is a flooded-core hydrocyclone that treats mixed gas-liquid fluid flow.

The next article will (re) discuss the Five-Steps of Sand Management and where multiphase desanding fits into this methodology. (Note: this is the subject of my current SPE Distinguished Lecture tour)

References:

- Rawlins, C.H. 2017. “Separating Solids First – Design and Operation of the Multiphase Desander”, paper 185658-MS presented at the SPE Western Regional Meeting, Bakersfield, CA, 23-27 April.