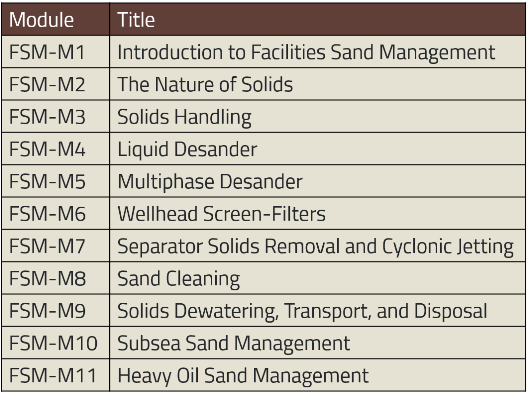

Facilities Sand Management (FSM) for Oil & Gas Production: Training Outline (B-FSM-011)

The material being presented in these weekly blogs comes from a training course developed for the upstream oil & gas industry. This course will be presented in whole or part at Society of Petroleum Engineers meetings in 2018, and can be given at client locations. The outline above lists the current 11 modules (more are being developed), with further information detailed below.

Technical Discipline

Primary: Projects, Facilities, and Construction

Secondary: Production and Operations

Target Audience

Engineers and operators involved with design and operation of facilities (onshore, offshore, or subsea) where sand production is an issue.

Learning Objectives

- Define and characterize oil & gas produced solids including key terms and concepts

- Design and specify piping, valves, and instruments for facilities with solids production

- Detail the five-step methodology for solids handling system design – separate, collect, clean, dewater, and transport – and how to integrate these steps into new or existing facilities

- Understand the operation and specify the design for key unit processes including liquid desander, multiphase (wellhead) desander, screen-filters, cyclonic jetting, and sand cleaning systems

- Identify a proper solids disposal route and how to design a dewatering and transport system into the solids handling system to meet the disposal requirements

Why You Should Attend

All oil & gas wells produce sand. Proper Facilities Sand Management simplifies production operations, extends facilities life, restarts shut-in wells, and can improve total hydrocarbon recovery.

Course Description and Topics Covered

Facilities Sand Management is tasked with the goal of ensuring sustained hydrocarbon production when particulate solids are present in well fluids, while minimizing the impact of these produced solids on surface equipment. Conventional sand management focuses on sand exclusion from the wellbore, either by production limits or completion design. Improper or failed completions result in high levels of sand production, and even proper completions will still pass some quantities of sand. An inclusion paradigm that all oil & gas wells produce sand, either now or in the future, deals with co-production of fluids and solids. A solids handling methodology incorporating separation, collection, cleaning, dewatering, transport, and disposal into new or existing facilities simplifies production operations, extends facilities life, restarts shut-in wells, can improve total hydrocarbon recovery, and allows sustainable hydrocarbon production.

Special Requirements

- Participants should be familiar with oil and water treatment equipment, processes, and systems – especially separations technologies

- Familiarity with mechanical design including ASME Section VIII for Pressure Vessels, ASME B31.3 for Process Piping, and API-6A for Wellhead Equipment would be useful

- Attendees need to bring relevant facilities designs and sand production problems to use as in-class exercises

Level of Learning

This is an intermediate to advanced course.

Instructor

Hank Rawlins, eProcess Technologies

13201 Northwest Freeway, Suite 800, Houston, TX

hrawlins@eprocess-tech.com

Contact me for further information if you are interested in hosting this training course at your company.