Facilities Sand Management: Particulate Solids Transport – Particles Settling in Separators (B-FSM029)

I’m a firm believer that solids should be removed from the flowline upstream of the production or test separator. See paper “Separating Solids First – Design and Operation of the Multiphase Desander” in reference below.

However, if sand does make to the production separator, it will settle in the low velocity zones – which happen to be the water section of your separator. You can remove the sand using cyclonic jetting (see Oil & Gas Facilities reference below).

But how do you calculate the quantity of sand and of what size that settles in your separator?

Industry Guidelines

The first thing I did was check industry standards and references on methods to calculate sand settling in separators. These did not provide what I was looking for.

- API 421 Design and Operation of Oil-Water Separators

- Amount of settleable solids determined by Standard Method 2540F or EPA Method 160.5 (same procedure) – uses 1 liter of sample in Imhoff cone for 1 hour – records amount directly

- NORSOK P-100

- Provision for jetting/pan system – no calculations

- Shell DEP 31.22.05.12-Gen.

- Provision for liquid spray/drain, reduce inlet velocity, add erosion allowance to inlet device – no calculations

- Surface Production Operations (Vol. 1) by Arnold and Stewart

- Provision for jets/pans – no calculations

- GPSA Engineering Data Book

- No discussion

In discussions with engineers at several operators (ExxonMobil, BP, Chevron, Statoil, etc.) the consensus was to base solids settling on Stokes approximation.

Stokes / Mass-Balance Method

Using this method (Stokes settling has been discussed in article B-FSM-24) I put together a simple procedure for estimating cut-size and quantity of settled solids. This uses a simple mechanistic, mass-balance approach detailed in the following steps.

- Calculate residence time of liquid (water) in vessel (weir height and inlet to weir distance)

- Calculate fall (capture) velocity as vertical distance divided by residence time

- Use Stokes Law to calculate size of particle matching capture velocity

- Particles with diameter greater than capture size are collected within the separator – smaller particles pass through with produced water

- Sum of all particles greater than capture size gives total amount of solids settled in separator

Example – Part 1: Calculate Capture Size

The following example is detailed in the two graphics as follows.

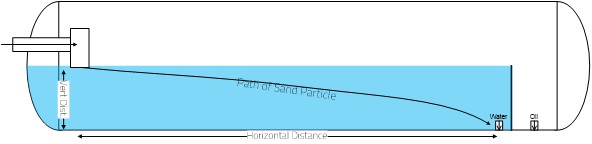

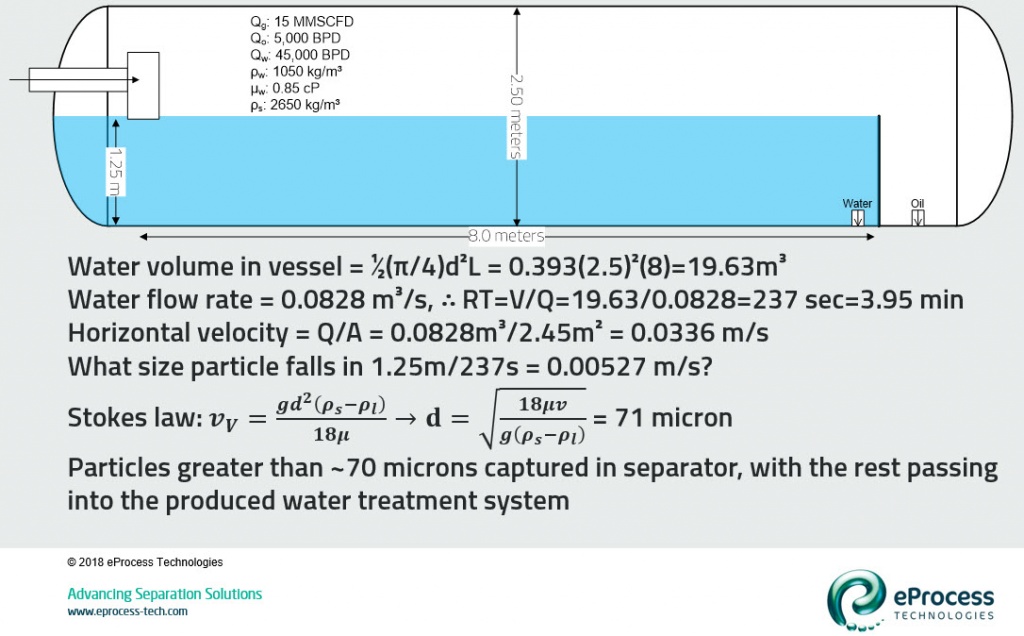

- Separator: 2.5 meters (8 feet) diameter, inlet-water length of 8 meters (~28 feet), water depth of 50% (shown on graphic below)

- Process Conditions: 50,000 BLPD at 90% water cut, produced water at 1050 kg/m³ density and 0.85 cP viscosity, and sand at 2650 kg/m³ density

- I’ve used a simple Stokes calculation (I didn’t check validity with Re, but this is good for a first pass)

- First calculate water residence time (using water volume in vessel and water flow rate), which is 3.95 minutes (237 seconds)

- Second determine what size particle falls the full depth (1.25 m) of water in 237 seconds = 71 microns. So, particles greater than ~70 microns are captured in the production separator and the rest passes to the produced water stream

- Yes, this is a very simplistic calculation that ignores turbulence, short-circuiting, internals, etc.

Example – Part 2: Calculate Capture Amount

For the next step, we’ll calculate the fraction of incoming solids that are captured in the separator.

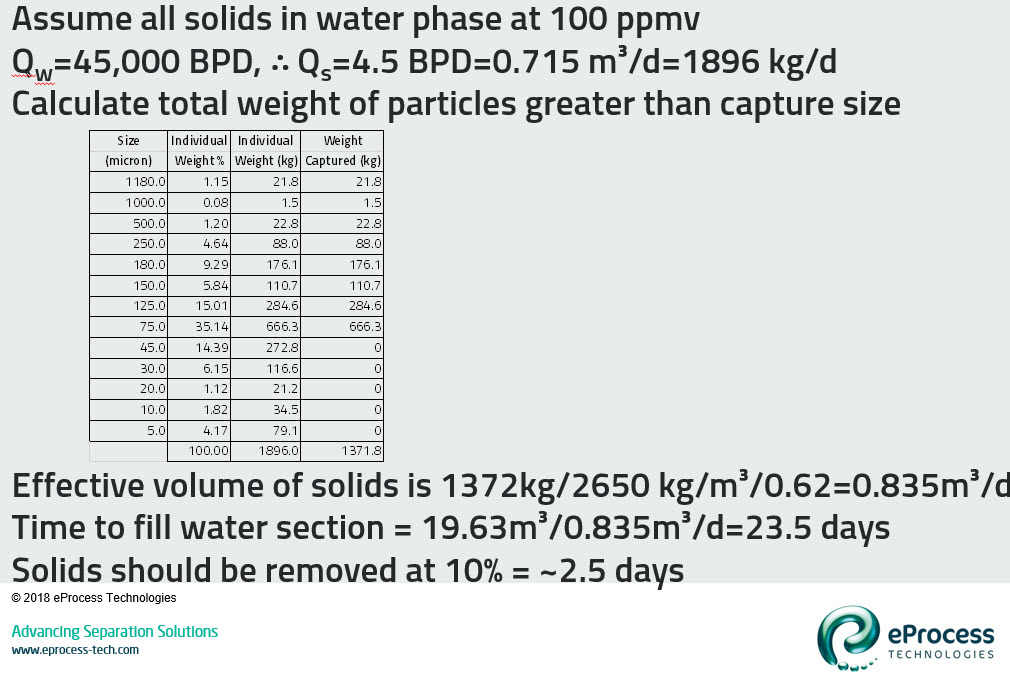

The base assumption in this case is that the solids (coming into the separator) are all in the water phase with a concentration of 100 ppmv. That results in 1896 kg/d of sand coming into the separator.

Using the inlet solids particle size distribution (a spreadsheet comes in very handy for this), we determine what portion of the solids are above and below the capture size. In this case 1372 kg/d (72%) of the solids are captured into the separator. The effective volume of these solids (using a 0.62 packing fraction) is 0.835 m³/d.

At this collection rate the water section will be filled in 23.5 days (leading to very poor primary separation). I recommend removing the solids at 10% level, which is at ~2.5 days of operation.

Settled solids should be removed frequently to prevent consolidation (mechanical effect) and binding (chemical effect). These effects will be covered in a future article on design of a cyclonic jetting system.

The next article will discuss instrumentation and valve selection for solids in oil and gas production.

References:

- Rawlins, C.H. 2016. Design of a Cyclonic-Jetting and Slurry-Transport System for Separators, Oil & Gas Facilities, Vol. 3, No. 1, February, pp. 38-46. https://doi.org/10.2118/166118-PA

- Rawlins, C.H. 2017. Separating Solids First – Design and Operation of the Multiphase Desander, paper SPE-185658-MS presented at the SPE Western Regional Meeting, Bakersfield, CA, 23-27 April https://doi.org/10.2118/185658-MS