eJECT™ Cyclonic Jetting

Send us an enquiry by downloading the Input Data Sheet, and return to us at sales@eprocess-tech.com

eProcess Technologies is a leading innovator of solids management technologies for the upstream oil & gas industry. The eJECT™ is a cyclonic-based solids jetting technology designed for the fluidization, removal, and transport of solids which have settled into a variety of production vessels and tanks.

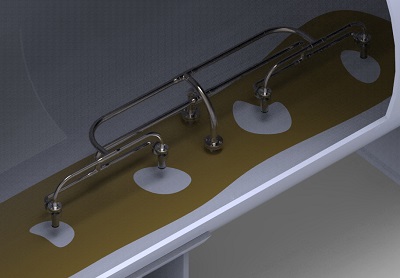

The eJECT™ operates with no moving parts; it uses motive liquid, supplied from most any source, to fluidize solids in a controlled manner within a defined region of the vessel.

For many years, eProcess Technologies has been a recognized leader in compact cyclonic technologies. It is from this leading technology base that the eJECT™ draws its core design.

Spray flow from the eJECT™ creates a controlled-vortex which interacts with settled solids across a 1.2 meter diameter zone. This area of the vessel is swept clean of solids using a low energy cyclonic pattern. The solids are evacuated through the center of the eJECT™ into a piping header for discharge from the vessel. An eJECT™ manifold can be designed to cover all or part of a vessel.

The discharged slurry created by application of the eJECT™ will be up to 70% solids by weight. This concentrated slurry makes it possible to handle solids in an efficient and effective manner as the amount of produced water delivered with the solids is minimized. When compared to conventional sand jetting systems, the slurry density is as much as nine times more concentrated. A 1” eJECT™ can transport up to four tons of solids per hour.

Typical eJECT™ Applications:

- Test and Production Separators

- Free Water Knockouts (FWKO)

- Corrugated Plate Interceptors (CPI)

- Storage Tanks

- Cyclone Accumulator Vessels

- Production Sumps and Pits

- Sand Cleaning Systems

- Slurry Transport Piping Systems

Spray & Discharge Flow:

Nominal motive spray flow requirements for a 1” eJECT™ are 5.0-7.5 m³/hr. The liquid is supplied at approximately 12-15 psi above the operating pressure of the vessel. The discharge flow is controlled in a range of 6.0-9.0 m³/hr. Differential pressure for discharge can be supplied from the vessel operating pressure, or with an outlet eductor.

Piping Design:

eProcess Technologies provides engineering for the design and application of the eJECT™ system. This includes manifold, header, and piping design which is critical for proper transport of the solids out of the vessel and to downstream handling. The piping design must allow for proper velocities to avoid settling and to avoid excess erosion. This design is verified through our proprietary models and in-house flow loop testing.

The eJECT™ Advantage:

- Efficient and effective removal of solids from oil & gas processes to prevent emulsions, instrument failure, erosion and corrosion, pump damage, or off-spec product

- On-line removal of solids from closed vessels without interruption of production

- Controlled vortex evacuation of solids without interference with fluid interface

- No moving parts – highly reliable

- Uses minimal flow and pressure of motive fluids – eliminates erosion

- Requires minimal support instrumentation and control equipment

- Concentrated discharge slurry minimizes need for downstream fluid handling equipment

- Slurry transport across long distances is possible

- Integrated with eProcess Technologies solids management technologies such as Sand Cleaning Systems and Bagging Stations