Physical Properties of Oil & Gas Particulate Solids – Morphology & Angle of Repose (B-FSM-015)

Morphology (form and shape) and angle of repose are two of the less commonly analyzed physical attributes of sand particles that effect facilities sand management design.

Morphology

The form and shape of a particle effects erosion rate, carrying potential in flow, settling rate, and stacking (dry and wet). This aspect can be considered the geometrical form of the particle. For sand grains this includes general shape, sphericity, roundness, and surface roughness. This is primarily a semi-quantitative analysis using a microscope with visual or image processing.

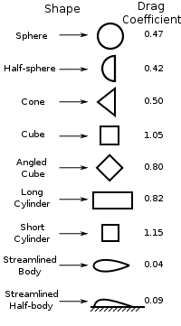

- Particle Shape: Stokes’ Law is used to calculate the terminal settling velocity for a at very small Reynolds numbers in a viscous fluid. As either the Reynolds number or the shape deviation from sphere increases, the relationship becomes less valid. A detailed treatment of particle settling will be discussed in a future article, but the relative effect of shape on settling rate can be approximated from the chart below. A cube has ~2X drag coefficient (e.g. ½ settling rate) compared with a sphere. Chart from Wikipedia here.

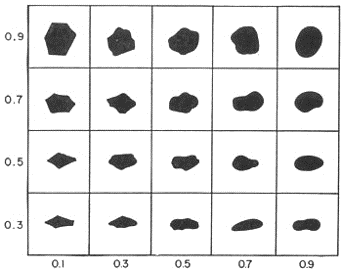

2. Roundness from a geological perspective gives the relative “smoothness” or surface roughness of a particle grain. A flat particle can be round, but may not be spherical. Mathematically roundness is the average radius of corners and edges divided by the radius of maximum inscribed circle, with a value range from 0-1. The closer to a value of 1.0 the smoother the particle.

3. Sphericity is a measure of how closely the particle approaches a sphere. Mathematically, the sphericity of a particle is the ratio of surface area of a sphere with same volume of particle to the surface area of the particle. It has a range from 0-1, with the higher value closer to a sphere. The most commonly used semi-quantitative analysis for both roundness and sphericity is the chart below taken from Krumbein and Sloss.

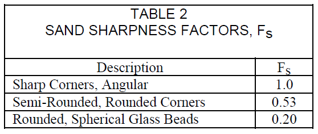

4. More importantly than settling rate is the effect of morphology on erosion. McLaury and Shirazi show that sand sharpness has a dramatic effect on erosion rate in piping in oil and gas production. This relationship will be discussed in detail in a future article, but the table of values from their article is shown below. Rounded particles have only 20% the erosive effect compared to sharp, angular sand. We will discuss this effect further when hypothesizing about in-situ sand treatment for subsea sand handling in a future article. If sharp angular sand can be treated (physically or chemically) to increase its roundness, then its erosive effect may be eliminated.

Angle of Repose

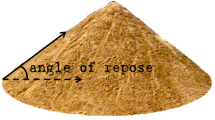

While not critical for storage of sand in oil & gas production, the angle of repose can be used to estimate the filling/removal of sand from cyclonic jetting systems. Typically measured with dry particulate solids, it is the steepest angle of descent relative to horizontal plane to which a granular material can be piled without slumping. This factor is a function of density, surface area, shape of particle, and coefficient of friction. The angle of repose is illustrated in the graphic below (from Wikipedia here).

While formal methods, such as tilting box or fixed funnel, can be employed, the simplest is to let the bulk materials free fall into a pile on a flat surface. The angle, measured upward from horizontal, will range from 0°-90°. Reported values for sand range from 35°-40° for dry, 15°-30° for water filled, and >45° for wet/damp.

Our experiments have found the angle to be steeper than the tabulated data, especially for that remaining after cyclonic jetting. An example is shown in the header picture. Sand settling in a water-filled vessel (e.g. separator or desander accumulator) will form a nearly level interface (<5° angle). A cyclonic jetting device used to evacuate sand from this vessel will not have a perfectly cylindrical affect. Due to the angle of repose the affected area from jetting will have a larger diameter at the sand-water interface (top of sand) compared to where the sand meets the vessel wall (bottom of sand). The resulting shape is an inverted truncated cone. Measurement of the resulting angle from our testing (using sand at 2640 kg/m³ and 100-400 µm average size) shows an effective repose angle of 45-60°. Knowing this parameter, and the effective sand removal area of your jetting system, can be used to estimate solids removal from a separator vessel.

Bibliography:

- Krumbein, W.C., and Sloss, L.L., Stratigraphy and Sedimentation, 2nd, San Francisco, W.F. Freeman, 1963.

- McLaury, B.S., and Shirazi, S.A., Generalization of API RP 14E for Erosive Service in Multiphase Production,” paper 56812 presented at the SPE Annual Technical Conference and Exhibition, Houston, TX 3-6 October 1999.

- Rawlins, C.H., Design of a Cyclonic-Jetting and Slurry-Transport System for Separators, SPE Oil and Gas Facilities, February 2016, pp. 38-46.