Partial Processing

Send us an enquiry by downloading the Input Data Sheet, and return to us at sales@eprocess-tech.com

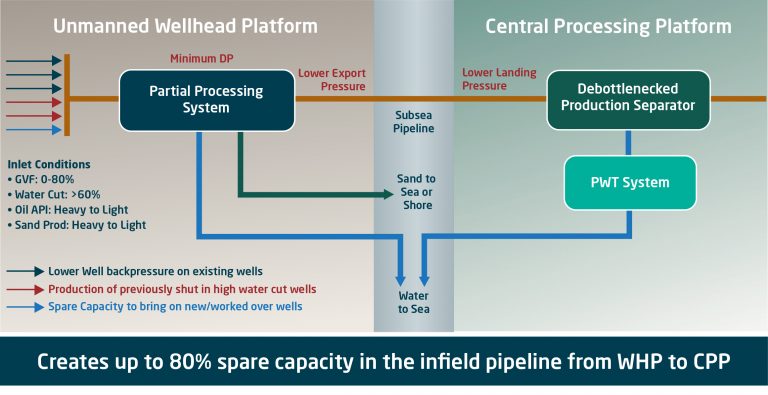

Partial Processing removes the bulk of a throughput constraining phase from oil and gas production with cyclone-based technology. Cyclonic equipment is key to this approach, with the technology “plugged in” to extend the operating envelope of existing processing facilities. 100% phase separation is not required, and “Partial” removal of the gas or water bottleneck unlocks production potential from mature or marginal fields – to realize a 50-400+% increase in hydrocarbon production.

Designed for easy retrofit within or around existing process equipment, a Partial Processing system maximizes the capability of existing facility footprint. Cyclonic technology offers 60-90% size and weight reduction of topsides modules, with corresponding capabilities for subsea and downhole applications. A Partial Processing skid can be installed on unmanned platforms with limited utilities or space and weight constraints.

Water Constraint:

High watercut production is treated at the production manifold for local treatment and disposal. Debottlenecking at this point opens capacity in flow lines, transfer piping, and process facilities, as well as corrosion & inhibitor dosage. Pre-Separation, Dehydration, and Deoiling cyclones are combined in series water removal and treatment, allowing existing facilities process oil and gas.

Gas Constraint:

Bulk gas removal upstream of a constrained production separator increase overall throughput while improving oil-water separation within the existing gravity vessel. An inline Auger separator removes up to 80% of the gas phase for bypass to the gas treatment facility.

Partial Processing Water Debottlenecking Flow Chart