Sampling of Particulate Solids in Oil & Gas Production – Part 1: Methods (B-FSM009)

Centrifuge Shakeout Samples from Wellhead Desander Inlet and Outlet

The 1st Rule of Sand Management is “Know what comes out of your well.” Sampling is required to know the properties and nature of the particulate material associated with well production. This article is the first of two that provide guidance for purpose, methods, quantity, and storage of solids samples from oil & gas production.

The four main purposes of sampling solids are;

- Concentration or quantity of solids in volume of liquid: given in a wide variety of values; including weight or volume percent or fraction, PPM, PPTB, mg/l, kg/d, gal/d, or others.

- Particle size analysis: includes total particle size distribution (PSD), average or mean size (D50), largest size (D100), distribution coefficients (e.g. for log-normal or Rosin-Rammler), and uniformity or gradation index (D90/D10 or D75/D25).

- Oil-on-solids content: the volume or weight percent oil on the sand particles.

- Contaminants: either on (adsorbed components like chemicals) or with (dispersed components like mercury) the solids.

The physical, chemical, and mineralogical properties of the solids are measured from these samples; however, these are generally secondary purposes for sampling.

Sampling of solids in oil & gas production is not easy. Because of the high operating pressure. And low concentration (compared to oil and water). And non-homogeneous dispersion (e.g. heavy solids bias within the flow patterns). Often a small needle valve is used to bleed a small portion of the flow stream into a sample jar. This works well for oil and water, but is insufficient to provide the quantity or quality of sample needed for solids, and the needle valve screens out large particles.

I’ve tried many different sampling methods in production systems and summarize the pros and cons of each below.

Millipore Filter

- Pros: simple and commonly available

- Cons: insufficient sample size for PSD

Shakeout

- Pros: simple and commonly available

- Cons: insufficient sample size for PSD

Bottle/Grab

- Pros: simple and commonly available – most common sample used

- Cons: sample valve (needle) screens out large sizes, generally does not provide sufficient quantity of solids for PSD

Collection Vessel or Dead Leg Trap

- Pros: simple to use and may be already available in system, provides both large and composite (time-summarized) sample

- Cons: may needed to added to system, does not collect small particles

Settled Material from Vessels/Tanks

- Pros: provides large/composite sample, captures settled particles (i.e. separable)

- Cons: requires shut-down to collect

- Photo below shows sample from wellhead desander accumulator discharge – large, composite (8-hour) sample sufficient for full analysis

On-Line Analysis

- Pros: provides in-situ analysis, captures data for entire PSD, can analyze for long periods of time – to show concentration trends

- Cons: does not provide physical sample for further analysis, requires specialized knowledge to operate properly

- Photo below courtesy of Jorin Limited

If I had to choose only one method from above, it would be to gather a large (5 kg) sample from settled material in a vessel or tank. From this sample, all data except for concentration could be gathered (and that can be estimated knowing production rate and amount in separator). The next best method would be to employ an on-line analyzer, which provides composite data for PSD and concentration. Millipore, shake-out, and bottle/grab samples do not provide sufficient or accurate data to design an FSM system.

Finally a bit on sample cleaning and storage. The methods employed depend on the analysis desired from the sample.

- If oil-on-solids analysis is to be performed then ship sample as-is (no cleaning or decanting).

- If measuring PSD and/or physical properties of the sand (with no oil-on-solids analysis) then allow sample to settle, decant free liquids, wash (hot water and soap), settle again, decant again, repeat as necessary – until the visual free oil is removed.

- A fully decanted sample can be shipped in plastic bag (double-layer) or other wide mouth container to enable easy removal at lab.

- The sample is cleaned at lab with hot water and solvent to remove all salts and hydrocarbons, then dried to produce free flowing particles.

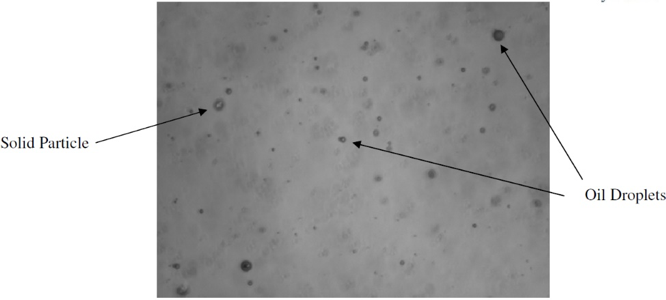

The bottle sample below shows composite sample used for oil-on-solids, PSD, and physical properties determination at lab. Several samples were combined into jar.

The next article will provide guidance on the sample size and number to accurately design a Facilities Sand Management system.