Separator Jetting – Design Procedure Parts 1-2 for Spray Jetting (B-FSM-118)

I fully believe that cyclonic jetting – covered in future postings – is superior to traditional spray jetting design. However, I realize that spray jetting has been around much longer and many operators may want to either design their own system or improve their existing hardware.

In this post I provide a design procedure for a traditional spray jetting system that should be followed by anyone using this technology in their separators. This design procedure is taken from Priestman et al. (reference at end of article) and is the best I have found. Get a copy of his paper and read thoroughly – then follow the design procedure. Their methodology was developed from lab tests using horizontal tanks at atmospheric pressure.

Design Procedure – Part 1

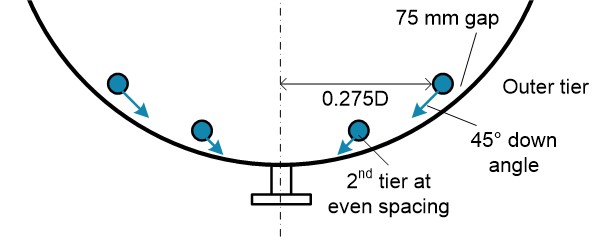

The outer jet header should be at the angle of repose of the solids

- At 35° the header is at 0.275D from vessel center (D= vessel diameter)

- Header placement at 75 mm perpendicular from vessel wall

- Jets angled at 45° down from horizontal

- Flat V-jet with 45° spray angle

Number of wash tiers (N) typically 1 or 2 (3 for very large D)

- Tiers are equally spaced

- Jet range is therefore 0.275D/N

The information above is shown graphically in the header figure.

Design Procedure – Part 2

Efficient jetting required (primarily) for minimal water use.

Operate at critical fluidization (F) factor – a dimensionless ratio

Jet Spacing = (𝟒𝑵∆𝑷𝒅^𝟐)/(𝑭∆𝝆𝒈𝑫^𝟐 )

- N = number of jetting tiers, typically 1 or 2

- ΔP = jet nozzle pressure drop, will be increase above vessel operating pressure

- d = wash jet nozzle diameter (>3 mm)

- F = fluidization factor

- Δρ = solid-liquid differential density (ρs-ρl)

- g = acceleration due to gravity

- D = vessel diameter

F is a function of particle size, shape, and surface properties

- Produced sand F=100×10-5 (specifically from Forties field in UK)

- Proppant F=250×10-5

Next week I will finish the discussion on the design procedure for traditional spray jetting systems.

References:

- Priestman, G.H., Tippetts, J.R., Dick, D.R., “The Design and Operation of Oil-Gas Production Separator Desanding Systems”, Trans IChemE, Vol. 74, Part A, March 1996, pp. 166-176.

- Rawlins, C.H., “Design of a Cyclonic Solids Jetting Device and Slurry Transport System for Production Systems”, paper 166118, presented at the SPE Annual Technical Conference and Exhibition, New Orleans, LA, 30 September – 2 October, 2013. https://doi.org/10.2118/166118-MS