Solids Handling for Upstream Oil & Gas Industry: Decision Tree and Key Items (B-FSM041)

With the dizzying array of terms and technologies and unknowns with sand management, where do we start?

“Begin at the beginning,” the King said (to the White Rabbit), very gravely, “and go on till you come to the end: then stop.” – Lewis Carroll, Alice in Wonderland

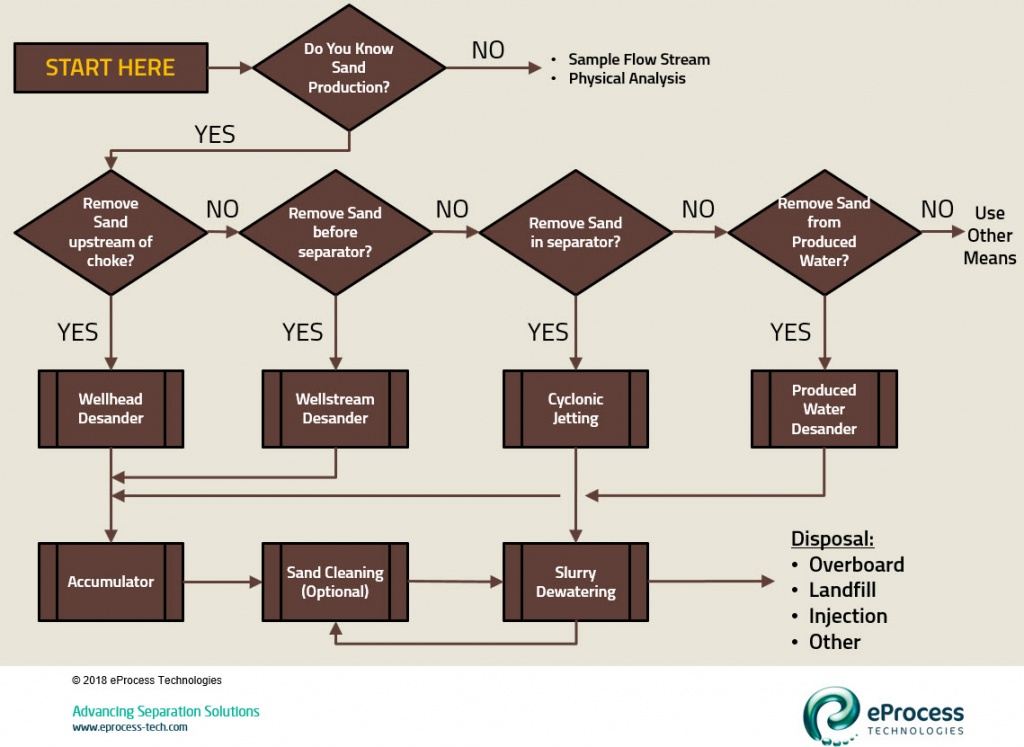

I’ve put together a very simplistic decision diagram on where to assist in the design.

Start with sampling, measuring, and characterizing your sand production. I find it amazing the millions of dollars spent on equipment designed with little or no data. Don’t build your system on poor data – or a foundation of sand. Don’t design any further until you know what is coming out of your well.

Can you remove sand upstream of your choke (Node 1)? If so, then do. It is the best place for sand removal. The only real limitations to pre-choke sand removal is low wellhead pressure (i.e. beam pump or ESP drive wells). Even in those cases a proper desander may only “use” 10-20 psi pressure which may be accommodated in overall design. High fluid viscosity (>200 cP, in-situ) is also a limitation – but with oil that heavy it will be hard to remove sand at any point. (Note: subsea wellhead desanders are available, so ocean floor removal is not a hurdle).

If you cannot remove upstream of choke, how about downstream (Node 2)? This location allows treatment of merged flow from multiple wells and will protect your separator from filling up. This location has the benefit of using the gas to assist in driving the cyclonic separation and removes the sand before while it is still warm.

You may not have a choice on Node 3 – if the velocities are low enough the sand will settle (and fill it up). A smartly designed cyclonic jetting system can be used to remove the collected sand – but it is always better to remove at Node 1 or 2 is possible.

Last option is Node 4 – removal from produced water. This is an important step to protect produced water treating equipment (deoilers, flotation cells, nutshell filters, etc.), and to protect injection systems. A produced water desander is a very economic insurance policy to keep the produced water treating system in top shape.

Once you know the proper place to separate, then follow the rest of the steps – collect, clean, dewater, and transport. Don’t skip any. Know where the sand needs to go and work backwards.

Key Items of Solids Handling Design

All oil & gas wells produce sand

- Know what comes out of your well.

- Don’t minimize production.

- Define what problem sand causes.

- Solve the right problem.

- Follow all the steps.

- Focus on the methodology – not a piece of equipment.

- Know where to put the sand!

All Solids Handling Systems to be evaluated through five steps

- Separate – Collect – Clean – Dewater – Transport

Design Facilities Sand Management into initial system

- Add taps and blinds (and space) for future equipment

- Add place for sand to go – don’t choke system

- Ensure parts can have material upgrade in future

- Spares management can be a philosophy but not the best

The next article will start the discussion of cyclone, hydrocyclone, and desander technology.

References

- Arfie, M., Marika, E., Purbodingingrat, E., Woodard, H., “Implementation of slurry fracture injection technology for E&P wastes at Duri oilfield”, paper 96543 presented at the SPE Asia Pacific Health, Safety, and Environment Conference and Exhibition, Kuala Lumpur, Malaysia 19-20 September 2005.

- Rafliansyah, A.P., Azkawi, A., Bharti, S., Oyemade, S., “Well cleanup issues in field with sand coproduction philosophy in Oman”, paper 107677 presented at the European Formation Damage Conference, Scheveningen, The Netherlands, 30 May – 1 May June 2007.

- Rawlins, C.H., “Design of a Cyclonic Solids Jetting Device and Slurry Transport System for Production Systems,” paper 166118-MS, SPE Annual Technical Conference and Exhibition, New Orleans, LA, Sep 30-Oct 2, 2013.

- Rawlins, C.H., “Sand Management Methodologies for Sustained Facilities Operations,” paper 164645-MS, North Africa Technical Conference & Exhibition, Cairo, Egypt, Apr. 15-17, 2013.

- Rawlins, C.H., and Wang, I. I., “Design and Installation of a Sand Separation and Handling System for a Gulf of Mexico Oil Production Facility,” SPE Production and Facilities, paper 72999, Vol. 16, No. 3, 2001, pp. 134-140.

- Veil, J.A., “Offshore Waste Management – Discharge, Inject, or Haul to Shore?”, 8th International Petroleum Environmental Conference, Houston, TX, November 6-9, 2001.