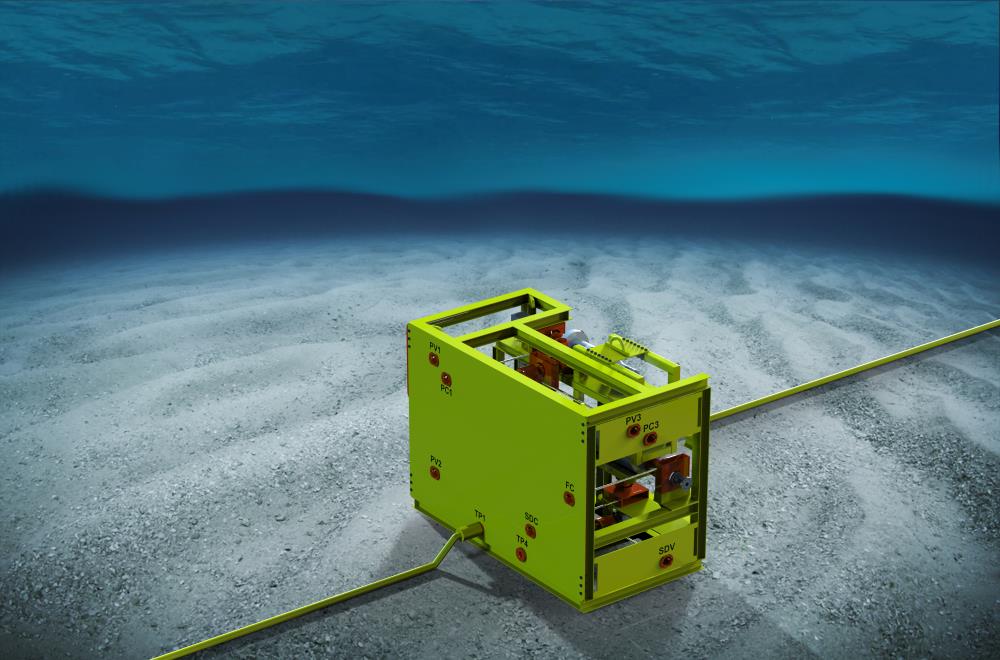

Subsea Separation – one part of multi-component system – that is Subsea Production

Send us an enquiry by downloading the Input Data Sheet, and return to us at sales@eprocess-tech.com

Our people are separating oil from other well products, in applications including Subsea Processing.

- Water removal debottlenecks flow lines, minimizes hydrate formation, and saves lift energy

- Solids removal improves pump & compressor reliability, minimizes erosion, improves flow assurance, and prevents separator plugging

- Gas separation allows for separate fluid boosting (compressor and pump) – bringing topsides to the sea floor

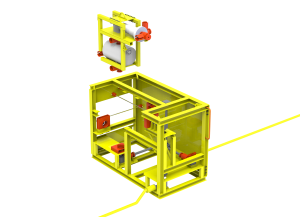

Proven technologies from topsides are deployable into subsea systems, and the primary hurdle now is packaging for remote use at 10,000 ft depth. Compact separation equipment, primarily cyclone-based processes, are the most applicable technologies for subsea packaging.

eProcess solution for Subsea Separation includes:

- Modular cyclone based compact production systems

- Flexible design specifications

- Significant size and weight reduction over conventional systems

- Easy to mobilize and install, “building blocks”

- Proprietary software tools

Capital Expenditure (CAPEX) Savings:

- Reduction in pipeline and component diameter

- Reduction in size and weight of downstream equipment and facilities

- In some instances, platform or other facilities may be eliminated

Operating Expenses (OPEX) Savings:

- Reduce complications with handling multiphase flows

- Reduced pumping requirements – lower fluid density requires less energy input

- Reduced chemical requirements – decreased hydrate formation and corrosion rates

- Increased downstream (platform) processing capacity