Gas Liquid Cyclones

Send us an enquiry by downloading the Input Data Sheet, and return to us at sales@eprocess-tech.com

eProcess Gas Liquid Cyclones (GLC) and Axial Flow Cyclones (AFC) provide cost effective, compact, and efficient gas-liquid separation. GLC’s are used either eternal or internal to production separators, whereas AFC’s are only used externally.

Multiphase fluids enter the top of a GLC tangentially and rotate from the action of centrifugal forces. The heavier liquids are forced to the wall of the cyclone and travel down to the underflow outlet, while the lighter gas phase migrates to a central core to exit the overflow.

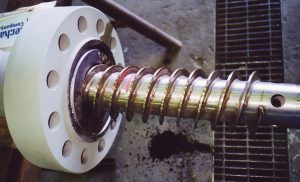

Multiphase fluids enter the base of an AFC and rotate from the action of centrifugal forces. Stationary helical vanes force the heavier liquids to the wall of the cyclone and the lighter gas phase migrates to the center. Dry gas is separated and directed to the outlet stream while the remaining partially degassed multiphase stream continues axially through the separator.

In Topsides applications the separated gas phase will be recovered via an elbow or crossover line, whereas Downhole the dry gas will be directed to the tubing-casing annulus.

Applications:

- Conventional Separator Debottlenecking

- Compact Degassing and Partial Processing

- Multiphase Metering

- Surface Gas Scrubbing

- Downhole Gas Liquid Operations and Optimal ESP Operations

Benefits:

- No moving parts, with low capital and operating costs

- Very compact in size and weight

- Foam Free gravity separator operation

- Insensitive to motion and highly flexible retrofit for debottlenecking applications

Operations:

- Highly flexible separation operation where either gas scrubbing or degassing is the primary separation objective

- The GLC provides an accurate gas liquid separation with dry gas and less than 1% by volume gas carry under into the liquid stream

- For gas scrubbing the AFC typically provides no liquid carry over when less than 60% of the inlet gas is removed, and for degassing operations typically no liquid carry over will occur when less than 80% of the inlet gas is removed

- Pressure drops are typically 5 to 20 psig for the GLC, and 50-80 psig for the AFC

- Typical sizes for the GLC are 1 to 6 inches diameter by 1 to 4 foot long, while AFC sizes are 4 to 10 inch diameter by 6 to 20 foot long

- Gas liquid processing capacities in the 100 BPD and 500 MSCFD up to the 25,000 BPD and 60 MSCFD range